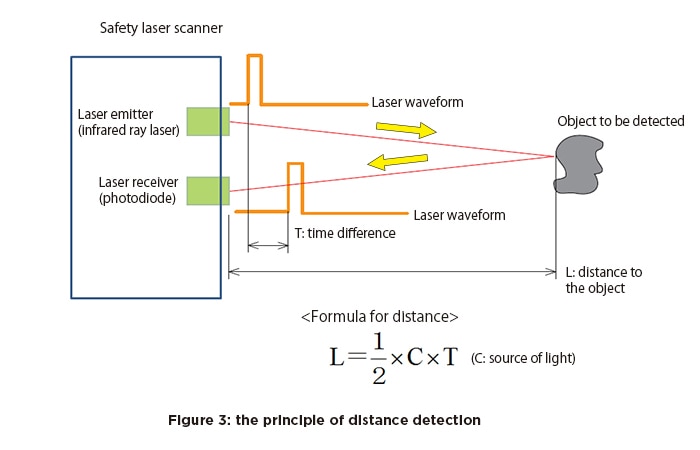

Principle of Distance Detection

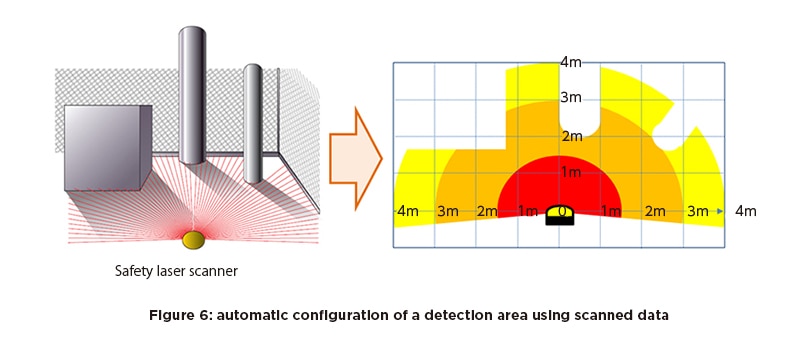

Laser scanners generally use infrared lasers, which are invisible to the human eye, to detect people.The distance to the detected object is calculated by measuring the time it takes for the laser beam emitted from the laser scanner to hit the detected object (a person) and reflect back to the scanner (Figure 3). Laser scanners also detect where a person is located in the warning or protective zone by calculating the distance by emitting laser beams in a fan shape at slightly different angles.