IDEC Safety Policy

IDEC, which celebrated its 75th anniversary in 2020, has contributed to the prevention and reduction of accidents and disasters at industrial sites for 70 years since releasing its first safety control product in 1950.

Mindful of our corporate creed “Respect for Humanity,” the IDEC Group pledges to conduct all business activities in ways that contribute to the economy and the global community. Based on this fundamental policy, we strive to create a safe and comfortable environment within the IDEC Group and throughout the global community. The IDEC Group, unrivalled in the pursuit of safety, aspires to a higher level of safety in all operations.

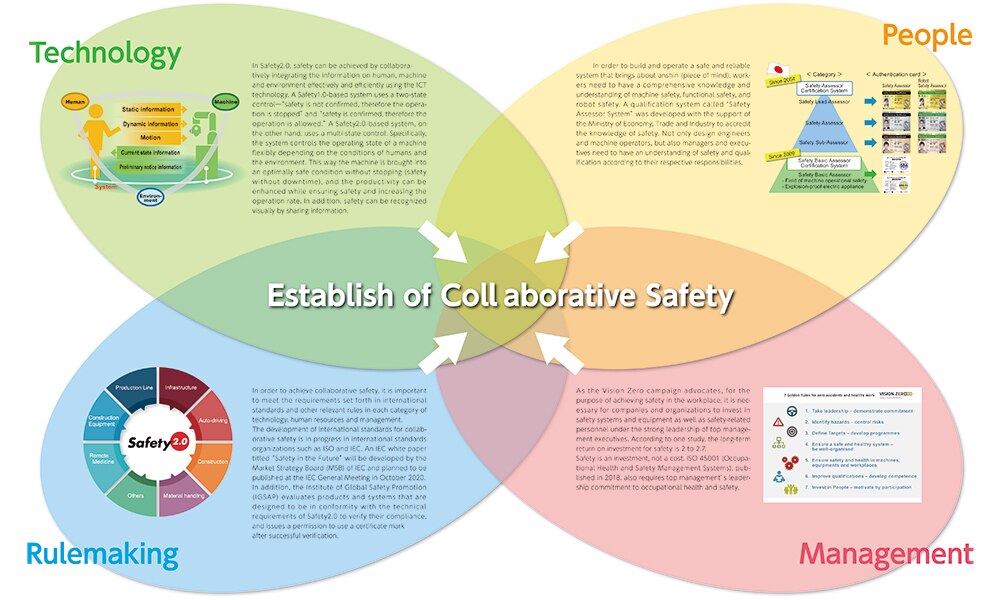

IDEC will pursue and achieve the highest level of safety and security in the world through the promotion of “Safety2.0”,which is a new-generation safety concept, and the spread of safety-related equipment.

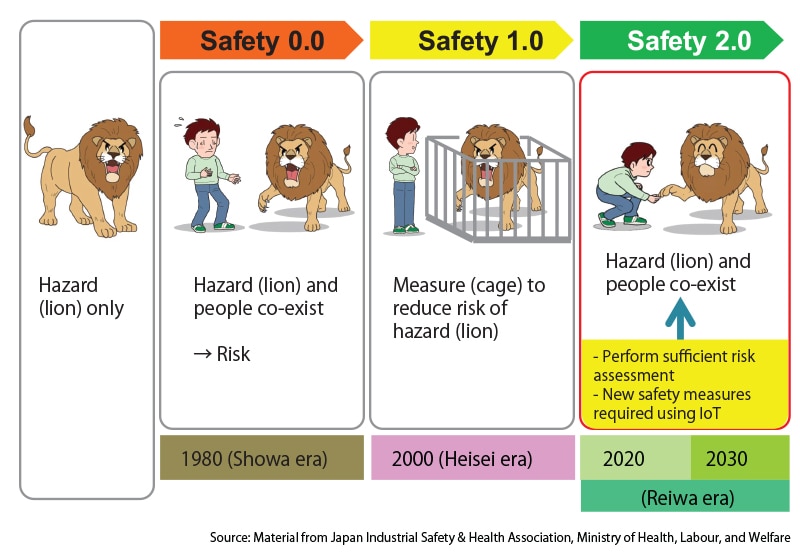

Transition(Changes) in Our Approach to Safety

Our approach to the concept of safety in the industrial field has changed with the times.

The most primitive approach is “Safety0.0,”, which ensures safety by relying only on the attention and judgment of people.

Put simply, the idea is for people to avoid accidents by paying attention when there are hazardous machines nearby.

However, people make mistakes and machines fail.

The concept of “Safety0.0” is insufficient to ensure safety if someone makes a mistake or a machine fails. So, there was a transition to “Safety1.0,”, in which safety is ensured at the stage of designing mechanical systems.

Further, in order to achieve greater flexibility and higher productivity, we are currently transitioning toward a new concept called “Collaborative Safety / Safety2.0”, in which people, things (machines), and environments share information and collaborate in order to achieve safety.

| Method of Ensuring Safety: Demonstration of Safety Functions | Principle | Specific Details | Features | Main Concept of Safety | Classification in Safety Science | |

| Safety 0.0 | Human attention | Protect oneself | Education, training, management, work standards, work manuals | Priority on production | Work safety | People: Human aspect (humanities) |

| Safety 1.0 | (Human attention) + technology | Safe machines and equipment | Inherently safety, Safeguarding, safety control, standards | Priority on safety | Machine safety | Things: Technical aspect (science) is added |

| Safety 2.0 | (Human attention + technology) + environment, information, and organization | Safety through Collaboration | Utilization of ICT technology, sharing of information | Balance of production and safety | Collaborative Safety | Environment: Organizational aspect (social science) is added |

If we compare a hazardous mechanical system to a lion, there is no risk as long as there is only a lion and no people nearby.

“Safety0.0” is a situation in which a person and the lion exist in the same space, and only human attention is relied upon to prevent injury. This involves a very high level of risk, and an accident could occur at any time. Next, “Safety1.0” ensures safety by enclosing the hazardous lion inside a cage, isolating it from people. Then, with “Safety2.0,”, the lion is removed from the cage to again coexist in the same environment as people after first conducting sufficient risk assessment and implementing new safety and security measures.