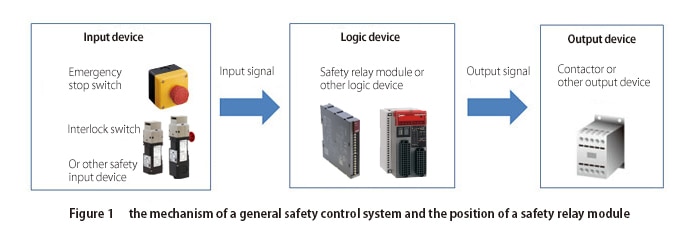

Safety relay modules and safety controllers are devices used in the safety-related part of control systems to perform control so that the machine operation is permitted only when safety is confirmed.

Specifically, it checks signals from inputs such as emergency stop switches and interlock switches, determines that it is safe, and controls contactors and other devices connected to outputs based on the results of that determination. In other words, the safety relay module and safety controller play a central role as the logic unit in the safety-related part of the control system (Figure 1).

We use cookies to ensure that we give you the best experience on our website. If you continue, you agree with our policy statement.

- Home

- Safety relay module / safety controller

Solutions

Reducing Costs

Compact components

Compact components

LED lighting

LED lighting

PLCs

PLCs

PLC/HMI programming suite

PLC/HMI programming suite

Extended-life components

Extended-life components

Reducing Costs

Reducing Carbon Footprint

PID controls/ thermal engineering

PID controls/ thermal engineering

Efficient power supply

Efficient power supply

LED lighting

LED lighting

12 VDC PLCs

12 VDC PLCs

Solar power system solutions

Solar power system solutions

Reducing Carbon Footprint

Safety and Beyond

Collaborative Safety

Collaborative Safety

Safety 2.0

Safety 2.0

Emergency-stop Safety

Emergency-stop Safety

Machine Safety

Machine Safety

Functional Safety

Functional Safety

Traceable Systems

Traceable Systems

Safety and Beyond

Minimize Downtime

Long-lasting Durable Devices

Long-lasting Durable Devices

Remote Monitoring and Control

Remote Monitoring and Control

Preventive/Predictive Maintenance

Preventive/Predictive Maintenance

Easy Replacements

Easy Replacements

Avoid Downtime Caused by Accidents

Avoid Downtime Caused by Accidents

Minimize Downtime

Optimize IIoT Practices

Remote monitoring

Remote monitoring

Traceable systems

Traceable systems

Production line safety

Production line safety

Smart inspection

Smart inspection

Optimize IIoT Practices

Explosion Protection

Machine Safety

Machine Safety

Reducing Maintenance

Reducing Maintenance

Explosion Protection

Manpower Shortage

Explosion-proof Cameras

Explosion-proof Cameras

Applying Robots

Applying Robots

Remote Monitoring and Control

Remote Monitoring and Control

Preventative Maintenance

Preventative Maintenance

Predictive Maintenance

Predictive Maintenance

Automation

Automation

Manpower Shortage

Safety Concept

Safety Concept

- Reducing Costs

- Compact components

- Compact components

- LED lighting

- LED lighting

- PLCs

- PLCs

- PLC/HMI programming suite

- PLC/HMI programming suite

- Extended-life components

- Extended-life components

- Reducing Costs

- Reducing Carbon Footprint

- PID controls/ thermal engineering

- PID controls/ thermal engineering

- Efficient power supply

- Efficient power supply

- LED lighting

- LED lighting

- 12 VDC PLCs

- 12 VDC PLCs

- Solar power system solutions

- Solar power system solutions

- Reducing Carbon Footprint

- Safety and Beyond

- Collaborative Safety

- Collaborative Safety

- Safety 2.0

- Safety 2.0

- Emergency-stop Safety

- Emergency-stop Safety

- Machine Safety

- Machine Safety

- Functional Safety

- Functional Safety

- Traceable Systems

- Traceable Systems

- Safety and Beyond

- Minimize Downtime

- Long-lasting Durable Devices

- Long-lasting Durable Devices

- Remote Monitoring and Control

- Remote Monitoring and Control

- Preventive/Predictive Maintenance

- Preventive/Predictive Maintenance

- Easy Replacements

- Easy Replacements

- Avoid Downtime Caused by Accidents

- Avoid Downtime Caused by Accidents

- Minimize Downtime

- Optimize IIoT Practices

- Remote monitoring

- Remote monitoring

- Traceable systems

- Traceable systems

- Production line safety

- Production line safety

- Smart inspection

- Smart inspection

- Optimize IIoT Practices

- Explosion Protection

- Machine Safety

- Machine Safety

- Reducing Maintenance

- Reducing Maintenance

- Explosion Protection

- Manpower Shortage

- Explosion-proof Cameras

- Explosion-proof Cameras

- Applying Robots

- Applying Robots

- Remote Monitoring and Control

- Remote Monitoring and Control

- Preventative Maintenance

- Preventative Maintenance

- Predictive Maintenance

- Predictive Maintenance

- Automation

- Automation

- Manpower Shortage

- Safety Concept

- Safety Concept

Safety relay module / safety controller | USA

Safety Relay Modules

A typical safety relay module contains several force guided relays and electronic components in an enclosure. It is also designed to be installed inside the control panel.(e.g. on a DIN rail)

Function of Safety Relay Modules / Safety Controllers in the Safety-related Part of a Control System

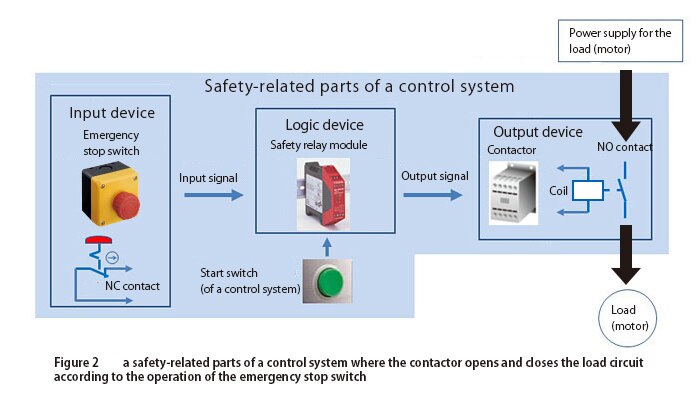

To start, the overall function of the safety-related part of the control system will be explained. As an example, we use a system with a safety function where a contactor opens and closes the load (motor) circuit in response to operation of an emergency stop switch (Figure 2). If the emergency stop switch is pressed while the motor is running, the motor is stopped immediately.

Emergency stop switches use NC (normally closed) contacts, which are normally closed (turned on) and output a signal (safety signal) that indicates a safe state. On the other hand, if some problem occurs and an emergency stop switch is used (pressed), the NC contact opens (turns off), and the safety signal is no longer output.

The safety relay module / safety controller outputs a signal to the contactor that permits the motor to run when the safety signal from the emergency stop switch has been input and the start (activation) switch of the control system has been pressed. When the contactor contacts are closed (turned on) and power is supplied from the power supply, the motor will start running. Note that the contactor contacts are NO (normally open) and are open (off) when there is no signal from the safety relay module.

In this type of safety control system, if the emergency stop switch is pressed while the motor is running, the safety signal is no longer input to the safety relay module, and the safety relay module stops outputting the signal to the contactor (the signal that allows the motor to run). In response, the NO contact of the contactor shall also open (turn off), and the motor shall stop.

Furthermore, when the emergency stop switch is pressed, even if the start switch is pressed, the safety relay module shall not output a signal (to allow the motor to run) to the contactor, and so the motor shall not run. To restart the motor, the emergency stop switch shall be reset (released from the activated state), and then the start switch shall be pressed separately.

The safety relay module / safety controller outputs a signal to the contactor that permits the motor to run when the safety signal from the emergency stop switch has been input and the start (activation) switch of the control system has been pressed. When the contactor contacts are closed (turned on) and power is supplied from the power supply, the motor will start running. Note that the contactor contacts are NO (normally open) and are open (off) when there is no signal from the safety relay module.

In this type of safety control system, if the emergency stop switch is pressed while the motor is running, the safety signal is no longer input to the safety relay module, and the safety relay module stops outputting the signal to the contactor (the signal that allows the motor to run). In response, the NO contact of the contactor shall also open (turn off), and the motor shall stop.

Furthermore, when the emergency stop switch is pressed, even if the start switch is pressed, the safety relay module shall not output a signal (to allow the motor to run) to the contactor, and so the motor shall not run. To restart the motor, the emergency stop switch shall be reset (released from the activated state), and then the start switch shall be pressed separately.

Safety Controllers

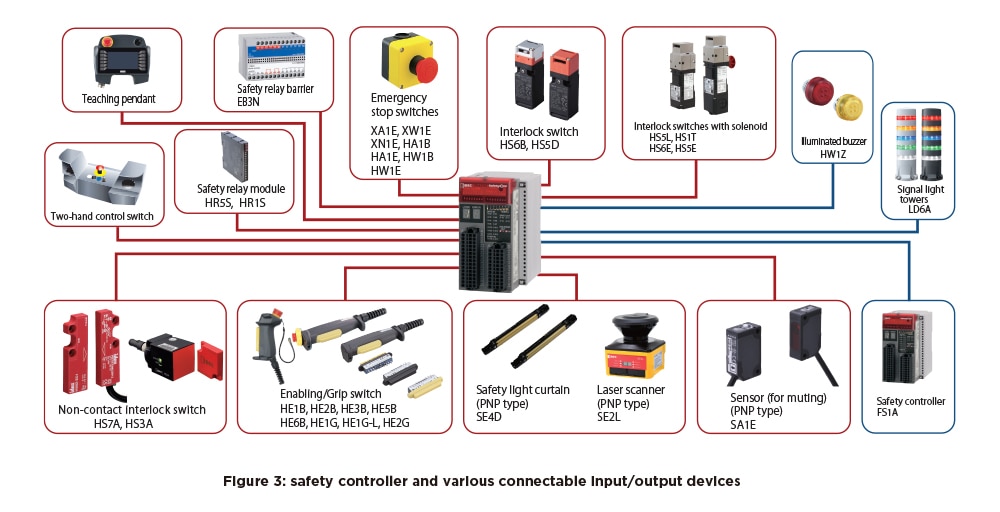

The safety controller is a safety device that, like the safety relay module, serves as the logic unit in the safety-related part of a control system.

As machines become more sophisticated and various safety devices are introduced, the safety-related part of control systems will continue to grow in complexity. The safety controller can be said to be a device that combines high safety performance with ease of use because the CPU functions can be used to easily set up the logic processing and combinations of various safety devices needed to ensure machine safety (Figure 3).

As machines become more sophisticated and various safety devices are introduced, the safety-related part of control systems will continue to grow in complexity. The safety controller can be said to be a device that combines high safety performance with ease of use because the CPU functions can be used to easily set up the logic processing and combinations of various safety devices needed to ensure machine safety (Figure 3).