Development of Human Resources to Support Safety |

Development of human resources capable of proposing safety and security to society

Safety training is provided to all employees to develop human resources who can propose safety and security to society.

In FY2021, safety training was expanded to our companies in Japan. In FY2022 and FY2023, safety education was provided to executive employees at our major overseas production bases in Suzhou, Thailand, and Taiwan. After FY2024, we plan to expand safety training, with local overseas executive employees serving as instructors to educate local general employees.

In the safety training, participants learn about IDEC’s safety history, safety concepts, safety products, and the latest information such as Vision Zero and collaborative safety (Safety2.0). They also take a comprehension test after the training to consolidate their knowledge.

*Vision Zero is an activity aimed at ensuring safe and healthy workplaces, based on the concept that all accidents and work-related illnesses that occur at workplaces can be prevented. If safe and healthy workplaces can be ensured, it will be possible for people to work under good physical, mental, and social conditions. It is believed that this will also lead to improved employee productivity and customer satisfaction.

*Safety 2.0 is a technological measure for collaborative safety that ensures safety by utilizing information and communication technology (ICT) and allowing information to be shared among people, things, and environments.

Training of professionals who can create safety, and qualified safety assessors

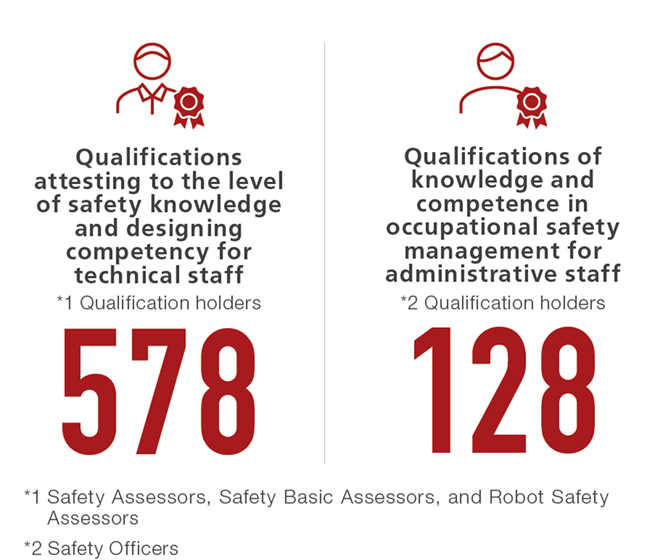

We encourage employees to acquire safety qualifications such as Safety Assessor and Safety Officer, and are working to train and develop human resources who can advance safety and ANSHIN principles in society.

We encourage employees to acquire safety qualifications such as Safety Assessor and Safety Officer, and are working to train and develop human resources who can advance safety and ANSHIN principles in society.

We cover the cost of taking qualification tests and renewing qualifications, and we have the highest number of qualified Safety Lead Assessors—the highest qualification—in Japan. We also encourage employees to obtain the Robot Safety Assessor qualification, which certifies that they possess basic safety knowledge in the field of robotics, and the Safety Officer qualification, which measures the knowledge and ability of management personnel to perform occupational safety management.

Leveraging our extensive experience in manufacturing and advanced knowledge of safety, we also provide safety consulting services that aim to achieve both safety and productivity, such as through risk assessment support at industrial sites and the proposal and development of risk reduction measures.

Proposal of safe manufacturing

IDEC develops devices intended for machine safety measures and, as a manufacturer, evaluates the risks inherent in products themselves during development processes and takes necessary measures to address them. We are developing qualified safety assessors throughout the company, in divisions such as the product planning department and sales department in addition to the development and design department, who are responsible for conducting internal and external risk assessments, and we have established a cycle in which safety professionals train new professional personnel. This “Safety DNA” has been developed and passed down to foster the safety culture of IDEC.

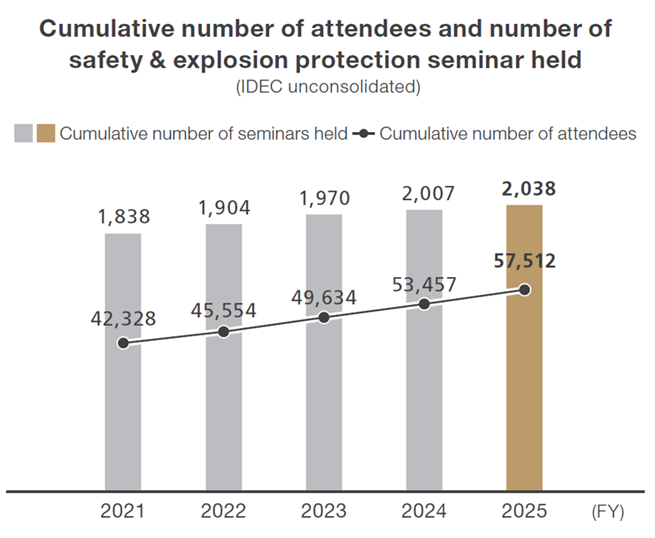

Holding safety seminars

We offer a variety of free, online safety seminars covering basic and applied knowledge and practical skills to help customers use safety-related and explosion protection products correctly.

Implementation of safety consulting

Utilizing our extensive experience in manufacturing and our advanced knowledge of machine safety, we provide safety consulting services aimed at achieving both safety and productivity by identifying sources of danger at industrial sites, assessing risks, and preparing and implementing measures to reduce them.