- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

- Automotive

- Solutions

- Explosion-Proof Lighting

- Explosion-Proof Lighting

- Robot Collaboration

- Robot Collaboration

- Dual-Action Interlocking

- Dual-Action Interlocking

- Smart Safety Gates

- Smart Safety Gates

- Large Inductors

- Large Inductors

- Small Equipment Safety

- Small Equipment Safety

- Solutions

- Brochure

- Brochure

- Automotive

- Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

-

Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

- Oil and Gas

- Solutions

- Automation

- Automation

- Control Panels in Hazardous Locations

- Control Panels in Hazardous Locations

- Machine Safety in Hazardous Locations

- Machine Safety in Hazardous Locations

- Solutions

- Oil and Gas

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

- Special Vehicles

- Solutions

- Construction Site Safety

- Construction Site Safety

- Illuminated Switches

- Illuminated Switches

- LED Pilot Light

- LED Pilot Light

- Auto Machinery

- Auto Machinery

- Rugged Switch

- Rugged Switch

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Robotics

- Solutions

- Robot Safety Switches

- Robot Safety Switches

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Warning System

- Robot Warning System

- Solutions

- Brochure

- Brochure

- Robotics

Smart Emergency Stop | USA

Prevent accidents with a more secure emergency stop mechanism

Switches providing secure stopping performance in case of an emergency

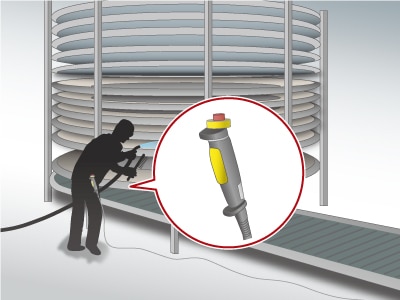

Emergency stop switch equipped in location not reachable by workers

Numerous measures have been developed to prevent industrial accidents in a wide variety of manufacturing sites. Although these include the proactive measures taken at food processing plants, there are still accidents involving workers having a body part or clothing caught up in machinery when equipment is suddenly operated by another person without noticing that maintenance or cleaning work is being performed, especially in the case of large processing equipment where it is not possible to have a sweeping view of the entire equipment. At some production sites there have been cases in which the worker realized that the machine was starting to operate and hurriedly tried to stop operation but the emergency stop switch was located too far away, preventing the worker from being able to press the switch. Inability to stop machine operation in an emergency is a huge problem. There is also the related problem of a worker slipping during normal operation and having a body part or clothing caught up in machinery, resulting in a failure to press an emergency stop switch. Finding a way to eliminate such risks certainly poses a great challenge to processing equipment designers.

Provide workers with a mobile switch allowing them to stop machine operation at any time

In order to solve this type of equipment safety problem, IDEC recommends operators carry our HE2G Grip Switches equipped with an emergency stop pushbutton switch as a risk-reducing solution. As the degree of danger when using large processing equipment increases when workers are positioned at some distance from the operating panel, use of grip switches with an emergency stop pushbutton switch that can be constantly held by a worker when performing cleaning and similar work enables an emergency stop to be performed from such positions. Now, workers in this food processing plant can work safely without fear of such physical dangers.

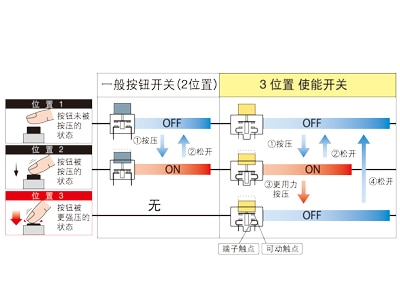

Taking into account the tendency of people not to act rationally during an emergency

There are also cases where a worker wants to move a rotary conveyor a little bit at a time to perform cleaning. The HE1G-L is equipped with a Three-Position Enabling Switch, making it perfect for such production lines. By lightly gripping the wearable grip switch, a worker can easily operate the equipment even in maintenance mode and stop operation just by removing his or her hand from the switch. The enabling switch cuts off the power circuit even if the switch is strongly gripped by a panicked worker due to a suddenly occurring emergency, providing the equipment with a secure emergency stop mechanism and increased safety. In this way, these enabling switches serve as a safety device that take into consideration the tendency for "humans to not act rationally in an emergency."

IDEC can provide you with total safety measures

IDEC provides reliability and results for safety with not only our wide and varied selection of safety equipment such as the enabling switches described here, as well as safety laser scanners, safety switches, and safety controllers, but also through the largest number of safety assessors in the industry. IDEC can provide consulting not only regarding safety equipment but you can also count on us to provide all manner of general safety solutions for your manufacturing site. Please feel free to contact IDEC if you have any questions or concerns regarding safety measures.